Fully automatic thermoforming machine for plastic lids, trays, and boxes. Supports PP, PET, PVC, HIPS, and PLA materials. Features 460×280mm forming area and 15–25 cycles/min speed. Ideal for food, medical, cosmetic, and hardware packaging. Custom molds and inline stacking system available.

model nomor :

YK-TF500PPNama Produk :

Plastic cup lid forming machineVoltase :

380V 3P 50HZKapasitas produksi :

15-25 cycle/minPenggunaan :

to produce plastic lids,medicine/food/daily/electronics/hardwarePelabuhan Pengiriman :

Shanghai/ningbo portWaktu Pimpin :

35daysBobot :

3200kg

The YK-TF500PP is a high-efficiency automatic thermoforming machine designed for the continuous production of plastic lids, trays, food boxes, and packaging components.

With a robust servo-driven system and forming area of 460mm × 280mm, it supports multi-cavity mold layouts, delivering reliable output at 15–25 cycles per minute.

✅ Ideal for:

Cup lids (flat, dome, sip-type)

Medical trays, pill packaging

Cosmetic blister packs

Stationery/electronic/hardware trays

Food packaging & disposable lunch boxes

|

Maximum Forming Area: 460mm × 280mm

Max Sheet Width: 500mm

Max Forming Depth: 50mm

This forming zone allows multi-up mold placement, such as 4–6 cavities for 90mm lids or 2–4 cavities for food containers—directly enhancing per-cycle yield and unit cost control.

🟩 Why it matters?

Larger forming area = higher productivity = fewer machine cycles per output volume.

|

PP

PET

PVC

HIPS

PLA

Roll-fed sheet materials (up to 500mm wide) in transparent or colored formats are supported.

The YK-TF500PP is specially optimized for PP (Polypropylene) sheets, making it an ideal solution for manufacturers focused on hot drink lids, takeaway food boxes, and heat-resistant trays.

PP material is lightweight, food-safe, and recyclable—but also requires precise temperature control and stable pressure during forming.

This model features enhanced heating zones, servo-regulated traction, and robust mold compatibility for perfect PP forming results.

✅ High forming accuracy for PP

✅ No deformation under heat

✅ Clean punching edges, ideal for high-speed stacking

✅ Supports transparent, semi-clear, or color PP sheet rolls

|

Why Choose YK-TF500PP for PP lid making?

|

|

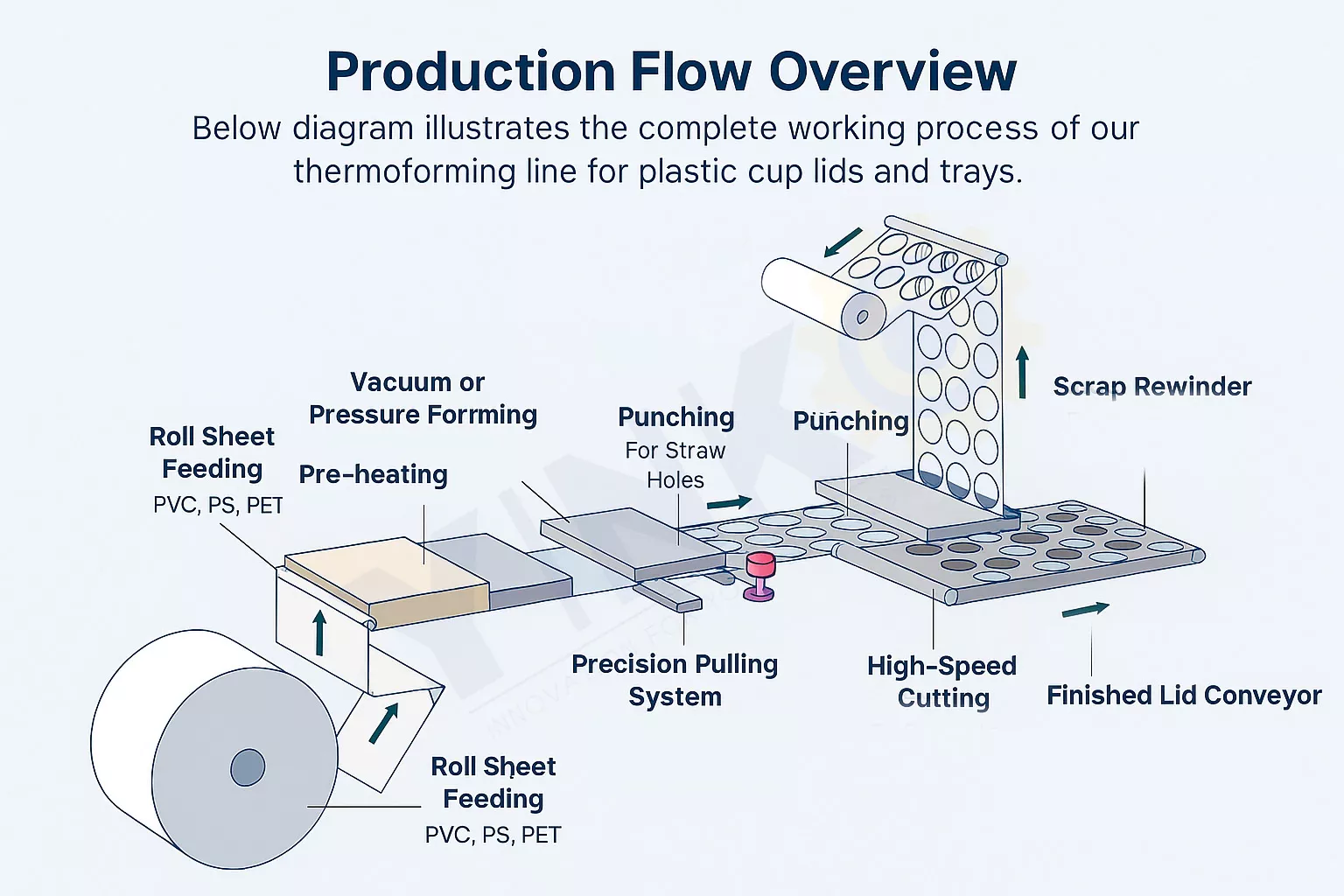

Sheet Feeding → Preheating → Vacuum/Pressure Forming → Hole Punching → Servo Indexing → Cutting → Product Stacking → Scrap Rewinding → Output

Every stage is automatically synchronized via PLC, ensuring stable speed and product consistency even under continuous 24/7 operation.

|

|

Spec |

Value |

|---|---|

|

Forming Speed |

15–25 cycles/min |

|

Max Forming Area |

460mm × 280mm |

|

Max Forming Depth |

50mm |

|

Sheet Width |

up to 500mm |

|

Power Supply |

24 kW |

|

Air Requirement |

>3 m³/min @ 0.6–1.0 MPa |

|

Mold Cooling Water |

60L/h tap or circulating water |

|

Machine Dimensions |

5300 × 1500 × 1900 mm |

|

Weight |

3200 kg |

Fully automatic: feeding → heating → forming → punching → cutting → stacking

Suitable for both transparent and colored sheet rolls

Servo-controlled pulling system for high positioning accuracy

CE-compliant safety cover and emergency stop mechanism

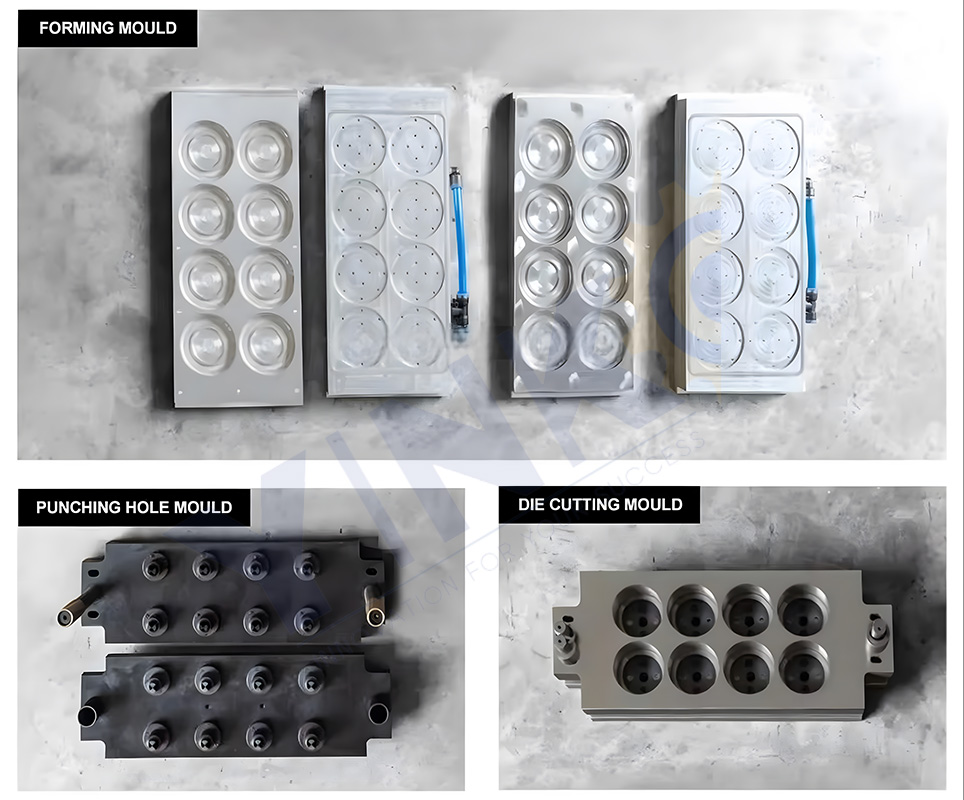

Easy mold change system, supports custom mold development

Scrap rewinder, automatic stacking & counting system

|

Drink cup lids (flat/dome)

Disposable food trays, lunch boxes

Cosmetic and skincare packaging

Medical trays, pill pack shells

Hardware & tool blisters

Custom OEM thermoformed parts

|

Beverage lid manufacturers

Takeaway food box factories

Cosmetics packaging suppliers

Medical kit and component tray production

Custom thermoforming OEM/ODM businesses

Q1: Can this machine work with PP materials continuously?

A: Yes. YK-TF500PP is optimized for PP sheets with enhanced heating zones, stable forming pressure, and precision mold compatibility. It’s suitable for continuous high-speed production of PP lids, trays, and containers.

Q2: What’s the maximum size of products I can make with this machine?

A: The machine supports a maximum forming area of 460×280mm and a forming depth of 50mm. Depending on the product shape, you can run multi-cavity molds for lids, trays, or shallow boxes.

Q3: Is mold customization supported? Can I use my own lid design?

A: Absolutely. We provide custom aluminum molds based on your CAD drawings or samples. You can also emboss your brand logo directly on the lid.

Q4: How many pieces can this machine produce per hour?

A: With 4–6 cavities per cycle and a speed of 15–25 cycles/min, production can reach 3,600 to 9,000 pieces/hour, depending on lid size and mold layout.

Q5: What additional units can I integrate with this machine?

A: The system supports expansion with automatic stacking, counting, and waste rewinding units. It can also be connected to a downstream packing or labeling line if needed.

Q6: Do you offer overseas support or remote installation?

A: Yes. We provide English manuals, remote video guidance, and on-site installation service through our experienced technical team for overseas customers.